14. Chemical mechanical polishing of plasma-modified Cu/polymer interfaces for advanced hybrid bonding

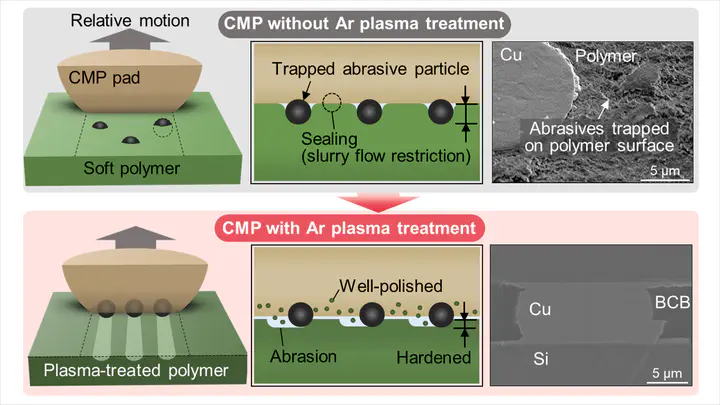

Hybrid bonding, referring to direct bonding between metal and insulator layers, has become a key technology for next-generation semiconductor packaging, enabling high-density interconnects, fast signal transmission, and a compact form factor. Polymer dielectrics such as benzocyclobutene (BCB) provide excellent insulation and adhesion but pose challenges for chemical mechanical polishing (CMP) due to their viscoelasticity. Here, a CMP-compatible strategy based on argon (Ar) plasma modification of BCB is proposed to enable effective planarization of Cu/BCB hybrid bonding interfaces. Ar plasma treatment increases surface hardness and brittleness of half-cured BCB and increases hydrophilicity. The resulting wrinkle structures improve the flow of abrasive particles and slurry, enabling a plowing-dominant removal mechanism for precision planarization. Modified BCB shows a removal rate of up to 17.3 nm s−1, over five times higher than untreated BCB, while Cu surface roughness is reduced from 51.4 to 3.0 nm. A time-dependent dishing model is developed to elucidate dishing mechanism and to control dishing geometry precisely. Using this model, a BCB dishing depth of 230 nm is achieved, supporting void-free and reliable hybrid bonding. Overall, this study presents a simple yet practical approach to CMP of soft polymer dielectrics and offers a promising solution to advanced heterogeneous integration technologies.