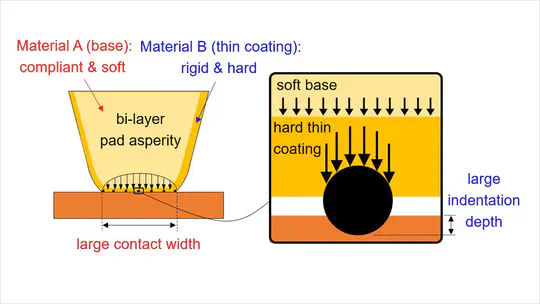

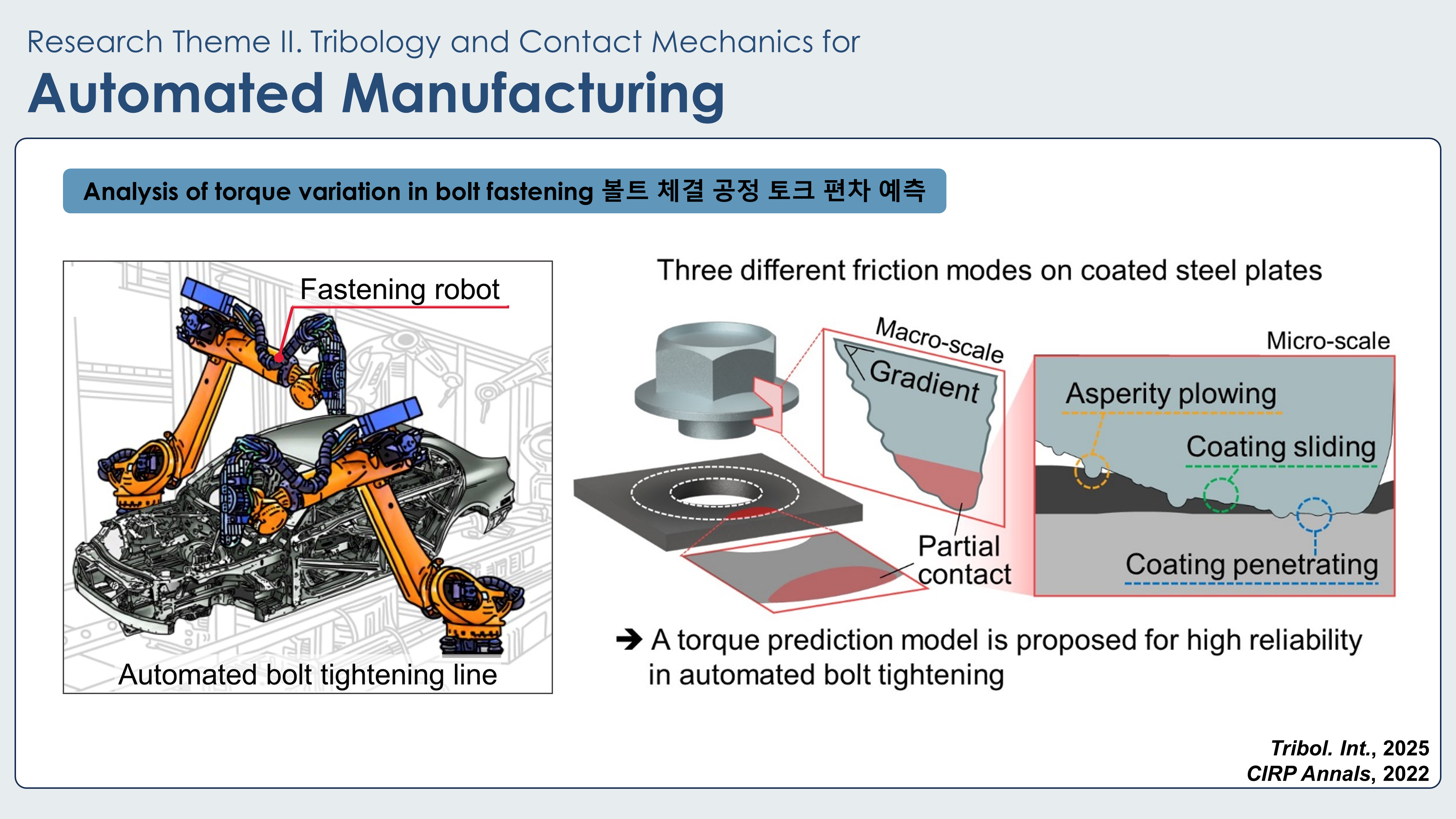

The interaction between engineered surfaces is an essential element in modern technology and industry, and understanding this interaction is key to unlocking new technological innovations. My research focuses on the phenomena arising from the physical contact between two engineered surfaces. The goal is to develop processing technologies that can create high-value, innovative products by precisely manipulating phenomena such as friction, wear, polishing, bonding, diffusion, adhesion, and deformation.

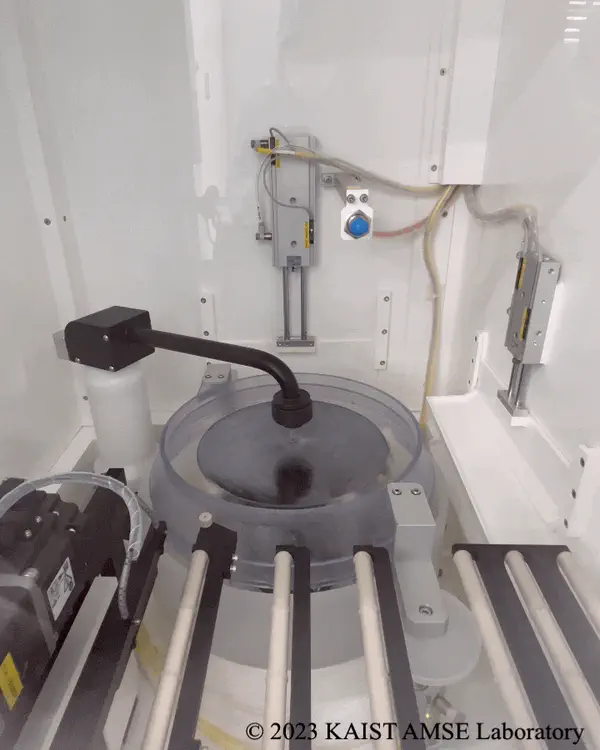

I am currently a Postdoctoral Fellow in Professor Sanha Kim’s group (Advanced Manufacturing and Surface Engineering (AMSE) Laboratory) at the Department of Mechanical Engineering, KAIST, where I also earned my Ph.D. in 2025 after embarking on this journey in 2020. In 2019, as an undergraduate at Hanyang University, I conducted graduation research in Professor Se-Jin Yook’s group. This academic journey has engaged me in various research projects within the field of mechanical engineering, enabling me to develop profound expertise and technical skills.

- Advanced Manufacturing

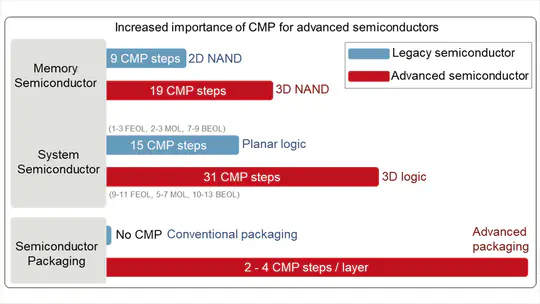

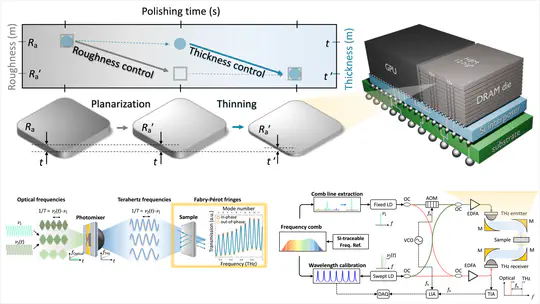

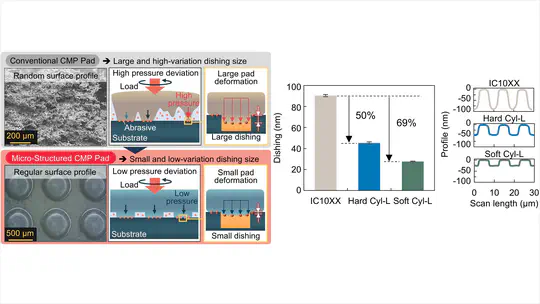

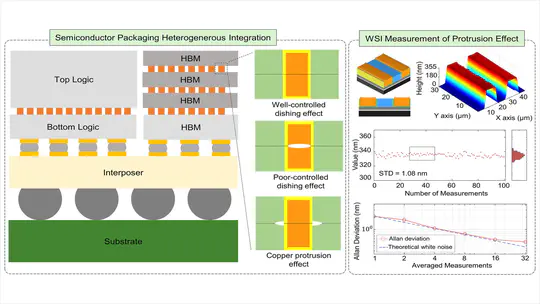

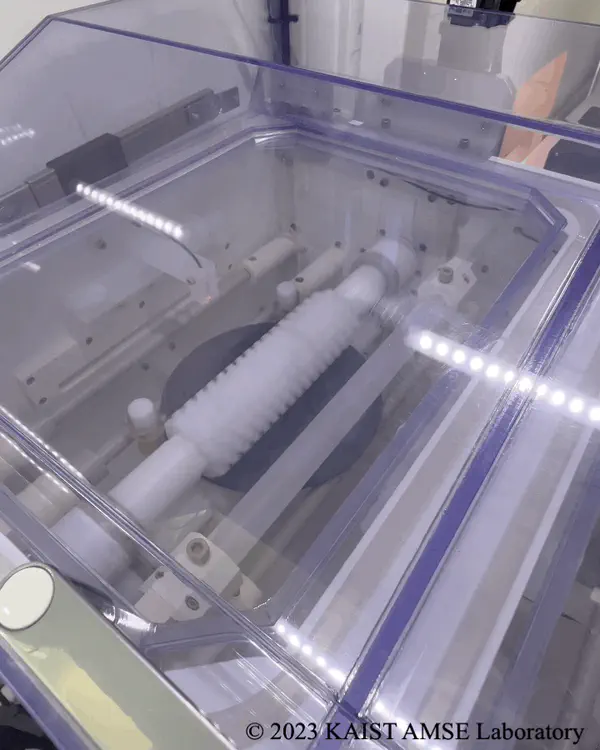

- Semiconductor Manufacturing

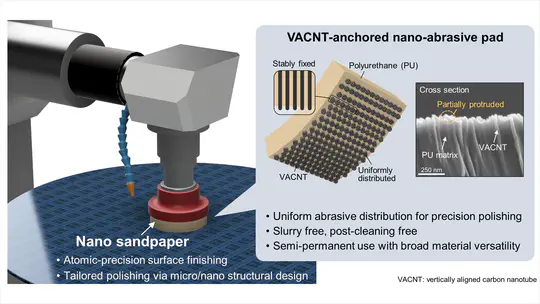

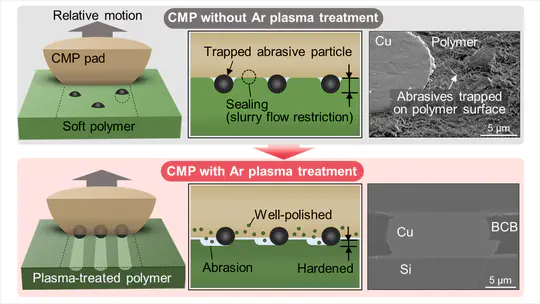

- Chemical Mechanical Polishing

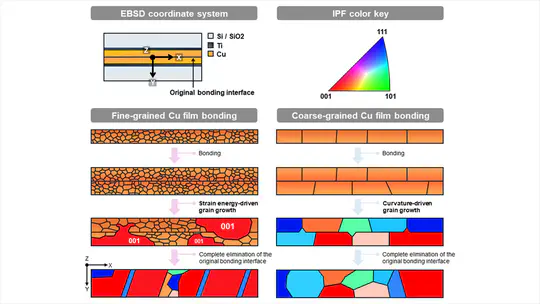

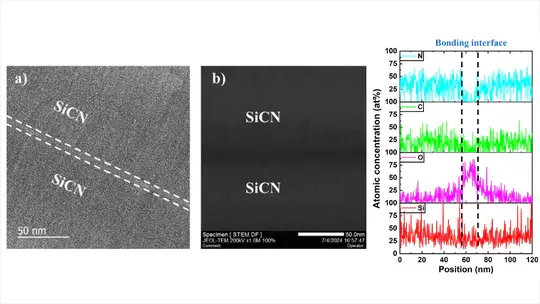

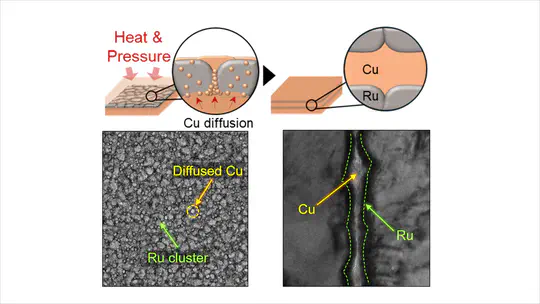

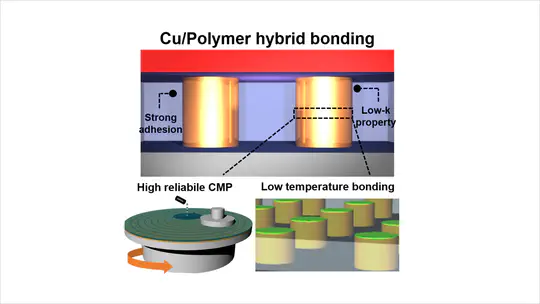

- Hybrid Bonding

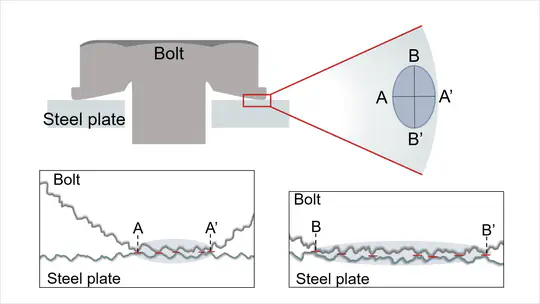

- Contact Mechanics

- Surface Engineering

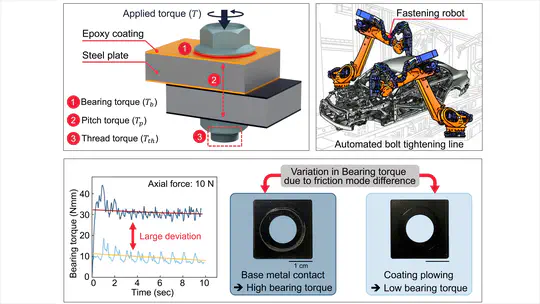

- Tribology

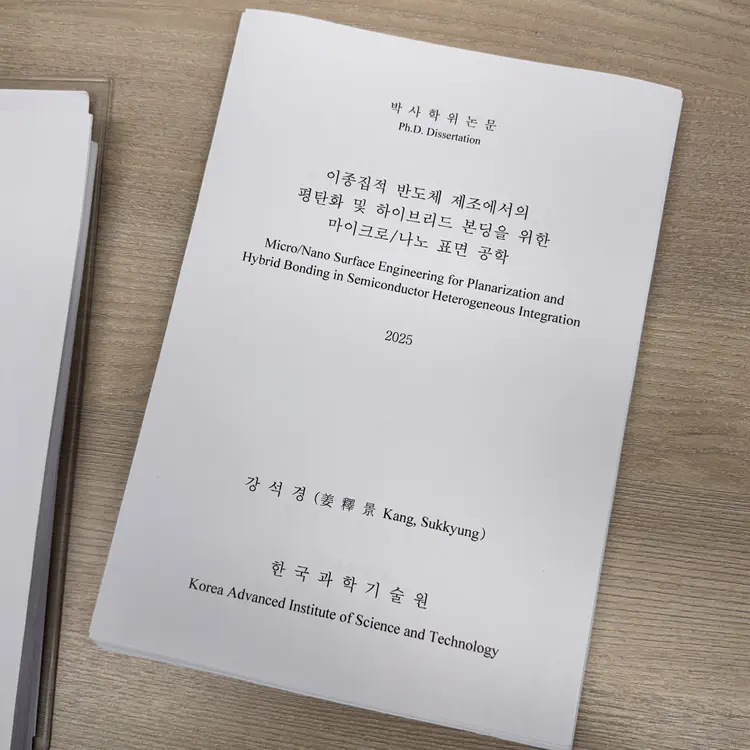

Ph.D. in Mechanical Engineering, 2025

Korea Advanced Institute of Science and Technology (KAIST)

M.S. in Mechanical Engineering, 2022

Korea Advanced Institute of Science and Technology (KAIST)

B.S. in Mechanical Engineering, 2020

Hanyang University

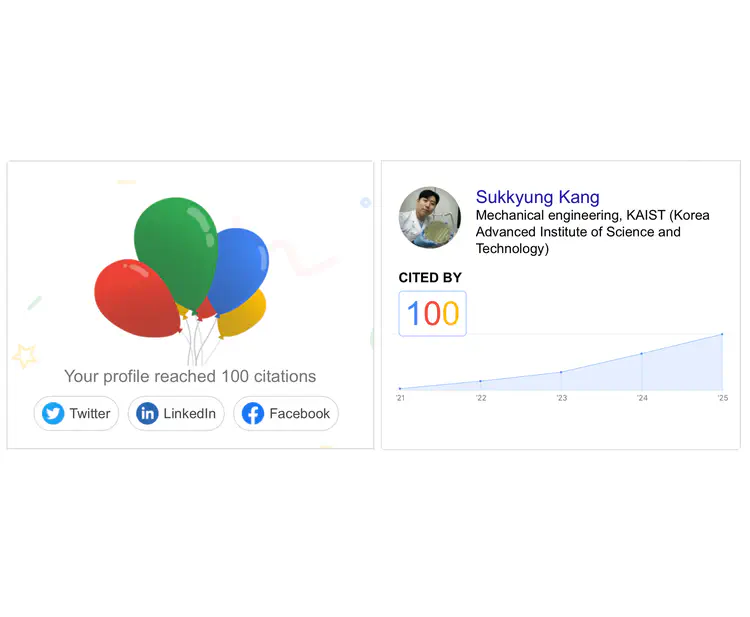

Awards and Honors

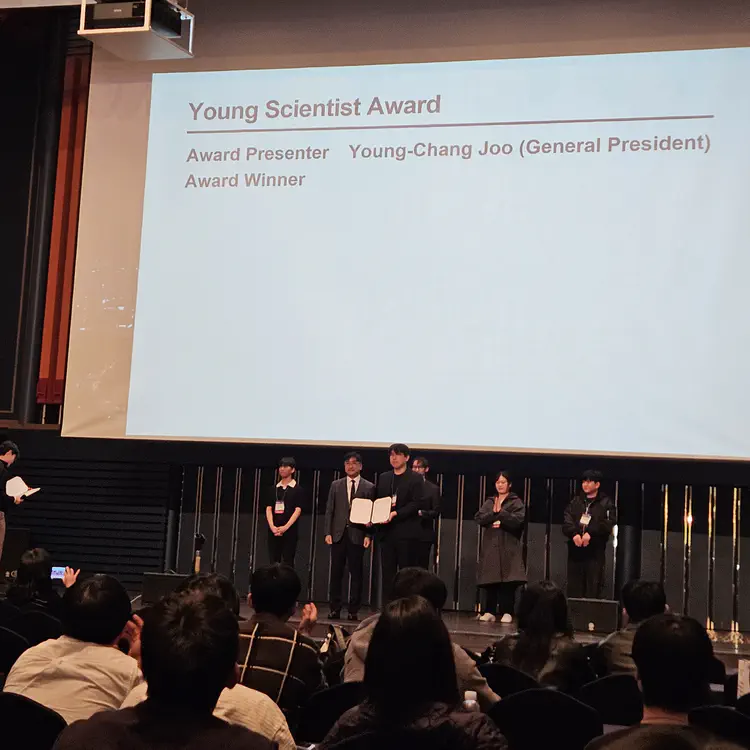

- 2025 Young Scientist Award at International Symposium on Microelectronics and Packaging (ISMP) (covered in KAIST ME News)

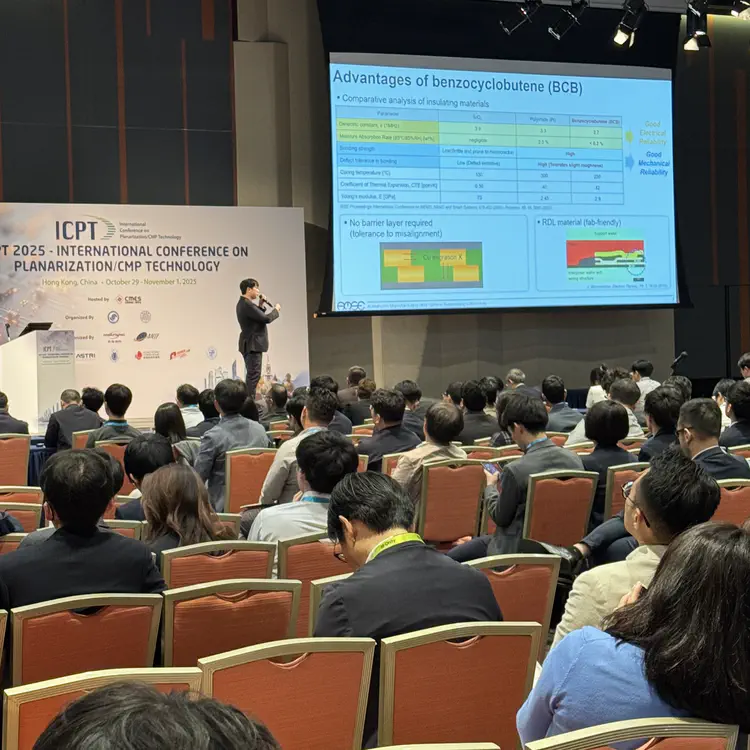

- 2025 Best Student Paper Award at International Conference on Planarization Technology (ICPT)

- 2025 Best Paper Award at Korean Tribology Society (KTS) (covered in KAIST ME News)

- 2025 Outstanding Paper Presentation Award from the Korean Microelectronics and Packaging Society (KMEPS) (covered in KAIST ME News)

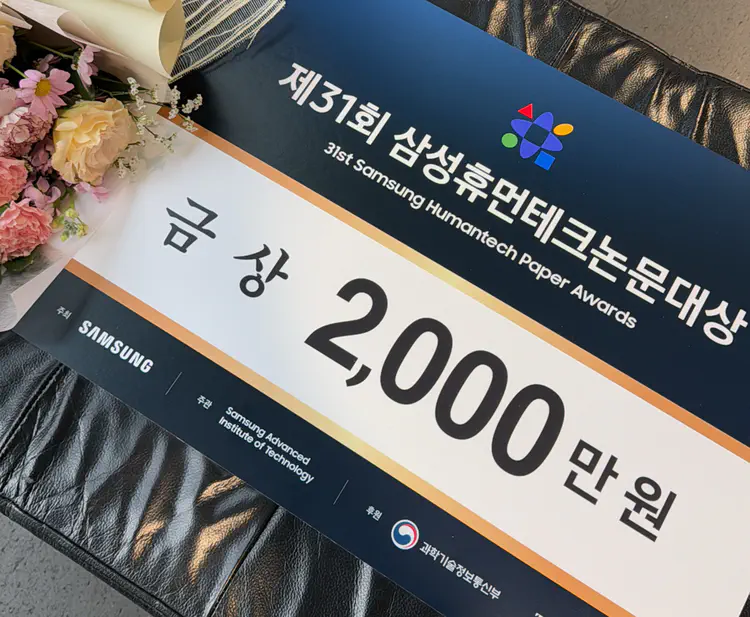

- 2025 Gold Prize, Samsung HumanTech Paper Award by Samsung Advanced Institute of Technology (SAIT) (covered in KAIST News)

- 2025 Silver Prize, Samsung HumanTech Paper Award by Samsung Advanced Institute of Technology (SAIT)

- 2024 Future Scholarship at Wooduk Foundation (covered in Major Korean Media Platforms)

- 2024 Best Paper Award at Korean Society for Precision Engineering (KSPE) (covered in KAIST ME News)

- 2024 Outstanding Paper Award at Korean Society of Automative Engineers (KSAE)

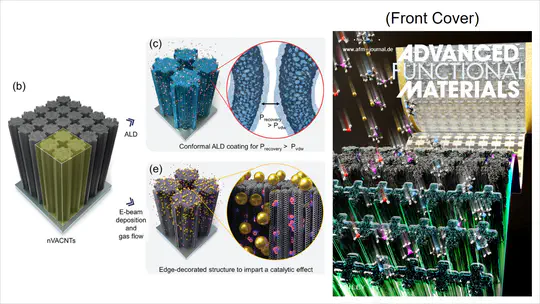

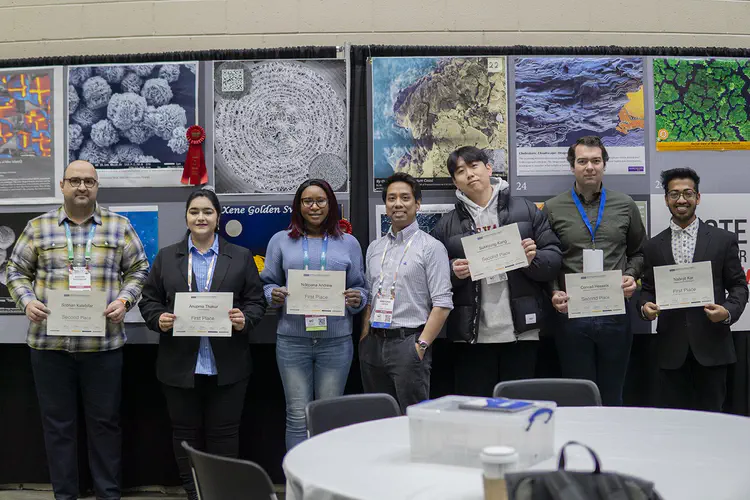

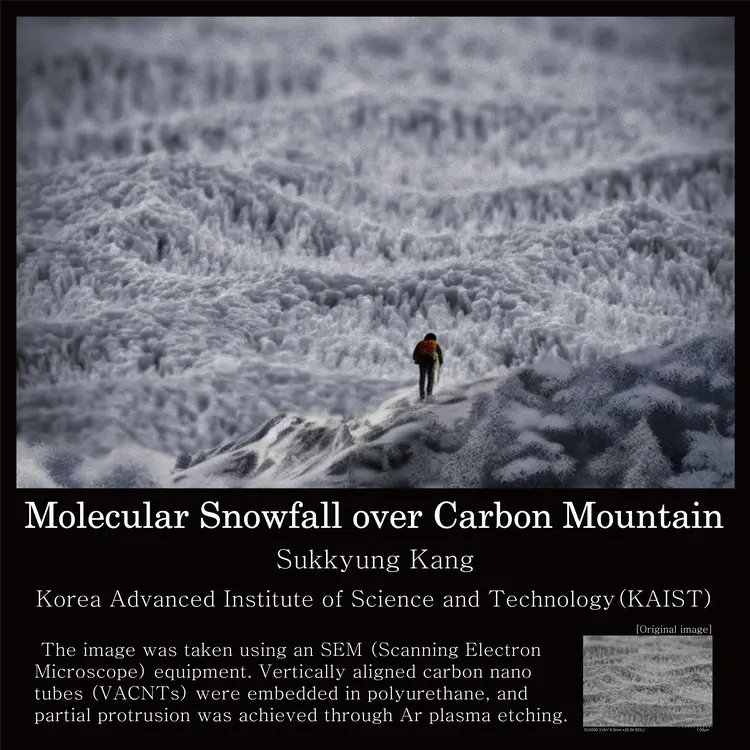

- 2023 Second Place in the Science as Art Competition at Material Research Society (MRS) (covered in KAIST ME News)

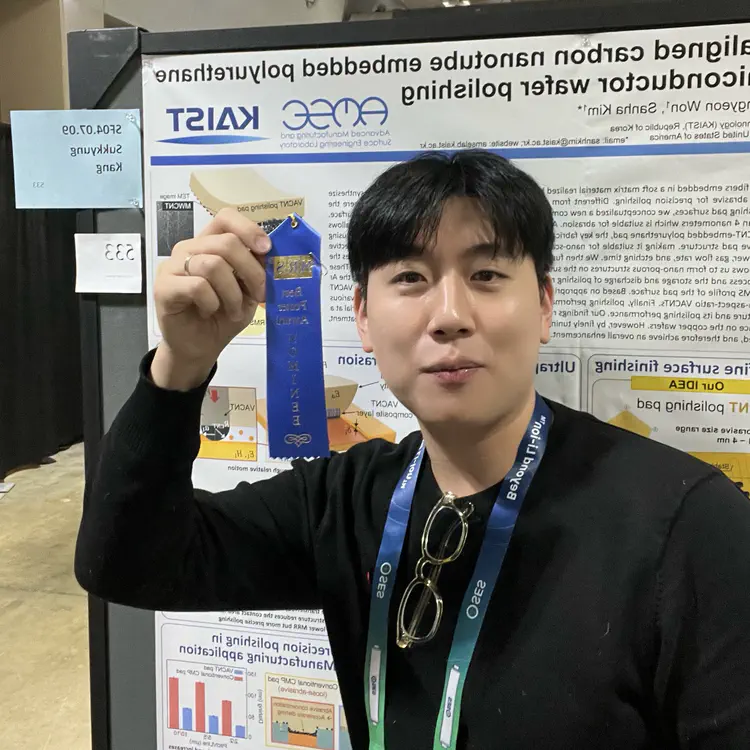

- 2023 Outstanding Student Poster Award at Material Research Society (MRS) (covered in KAIST ME News)

- 2022 Best Oral Presentation Award at International Conference on Electronic Materials and Nanotechnology for Green Environment (ENGE)

- 2022 Best Collaborative Patent Award at KAIST & Samsung Electronics

- 2022 Best Paper Award at Korean Society for Precision Engineering (KSPE) (covered in KAIST ME News)

- 2021 Outstanding Paper Award at Korean Tribology Society (KTS) (covered in KAIST ME News)

- 2020 Outstanding Paper Award at Korean Tribology Society (KTS)

- 2020 Summa Cum Laude BS in Mechanical Engineering, HYU

- 2019 President’s Award in Capstone Design Fair, HYU (covered in HYU ME HOT News)

- 2022 Outstanding TA Award in Education 4.0 Q Program, KAIST

- 2022 Best Tutor Award in Freshman tutoring program, KAIST

- 2021 Best Tutor Award in Freshman tutoring program, KAIST

- 2018 Best Tutor Award in Foreign student tutoring program, HYU

Research Themes

Journal Publications

Patents

(Total: 21, Granted: KR 3 / JP 1, Applications: KR 7 / US 4 / EP 2 / JP 1 / CN 2 / TW 1)

- KR Patent 10-2539172

- JP Patent 7704355

- US Patent Application 18/289,189

- EP Patent Application 21964180.0

- CN Patent Application 202180099397.2

- (PCT/KR2021/016560)

Composite polishing pad including highly abrasion-resistant thin film coating bound with carbon nanotubes, and method for producing the same - KR Patent 10-2531705

- US Patent Application 18/289,607

- EP Patent Application 21964181.8

- JP Patent Application 2023-571624

- CN Patent Application 202180099396.8

- (PCT/KR2021/016562)

Composite polishing pad including carbon nanotubes, and method for producing the same - KR Patent 10-2625829

- US Patent Application 19/061,232

Fixed-abrasive pad using vertically aligned carbon nanotubes and fabrication method for the same

(covered in KAIST Promising Commercialization Technologies Catalog) - KR Patent Application 10-2022-0002523 (Received Best Collaborative Patent Award)

- US Patent Application 17/805,735

- TW Patent Application 111121265

Polishing pad, chemical mechanical polishing apparatus including the same, and method for manufacturing semiconductor device using the same - KR Patent Application 10-2025-0091017

Electrical signal measurement system having a hierarchical surface microstructure impregnated with conductive material - KR Patent Application 10-2024-0110413

Fixed-abrasive polishing pad using vertically aligned carbon nanotube and method of manufacturing the same - KR Patent Application 10-2024-0058665

Polishing processing method and polishing processing equipment - KR Patent Application 10-2023-0187811

Plastic molding device for polishing pad, chemical mechanical polishing device including same, and method of controlling surface roughness of polishing pad using same - KR Patent Application 10-2023-0139596

Semiconductor circuit manufacturing method - KR Patent Application 10-2020-0134670

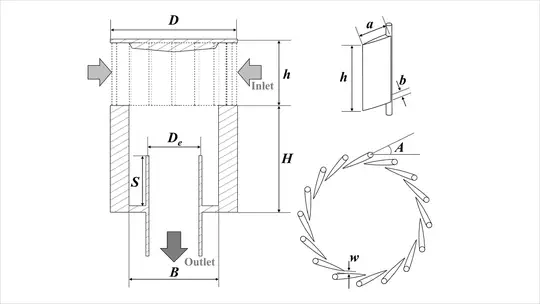

Design Method of Ionizer Anti-Virus Ventilation and Ventilation System for Protection Using a Voltage Type Copper hierarchy Filter