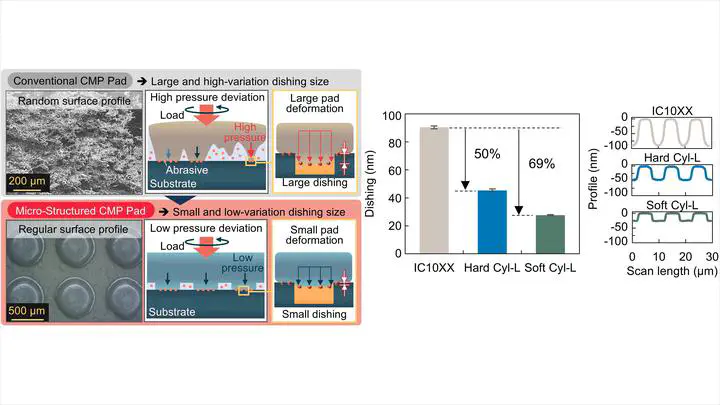

Dishing is a critical defect in chemical mechanical polishing (CMP) that affects the mechanical reliability and electrical performance of hybrid bonding interfaces in semiconductor packaging. This study explores that micro-structured pads with welldefined asperity design can minimize CMP dishing. A theoretical model identifies asperity area, height variation, and modulus as key factors influencing contact pressure and dishing. Experimental results validate the model, demonstrating a 69% reduction in dishing with a soft cylindrical pad compared to a commercial pad. This improvement is attributed to increased real contact area and uniform pressure distribution due to minimized height variation and material compliance.