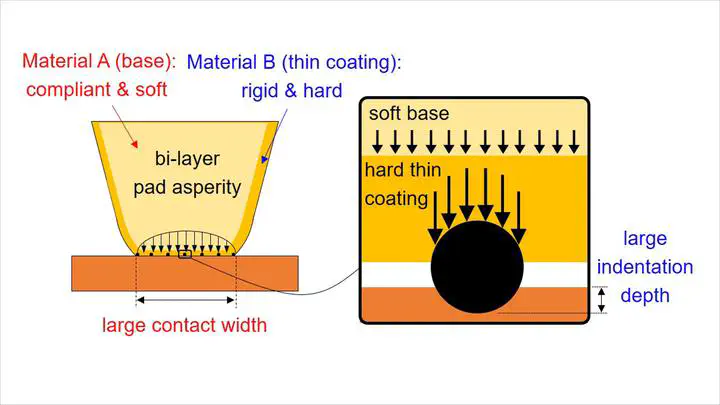

Pad asperities in chemical-mechanical polishing (CMP) provide necessary forces for mechanical abrasion. This article investigates the abrasive behaviour of polishing pads at the asperity contact scale. A contact mechanics model predicts that compliant and soft asperities or rigid and hard asperities may solely achieve either large contact area or high indentation depth respectively, whereas bi-layered asperities can enable both the enlarged contact and deep abrasion. Hemispherical pad micro-asperities with precise dimensions, including the new bi-layered design, were fabricated using thermal reflow and micro-replica molding techniques and their polishing behaviours were experimentally compared using a pin-on-disk polishing setup.