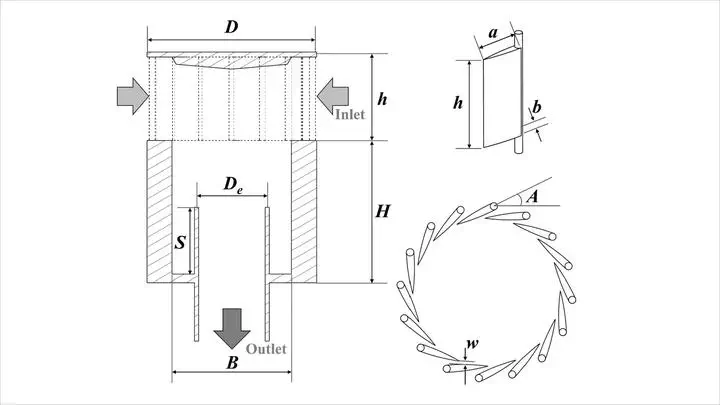

The cyclone separator, which is commonly used for size classification and collection of aerosols, have sampling bias that depend on the installation direction of the inlet and significantly limit the change in cutoff size. In this study, these shortcomings were addressed in the developed cutoff size adjustable omnidirectional inlet (CSAOI) cyclone separator, which can suction aerosol from all 360° directions and allows the adjustment of cutoff size without the need to change cyclone geometry or operating flow rate. Although the aerosol was suctioned from the side in a similar way to conventional tangential inlet cyclone separators, an omnidirectional inlet was implemented by installing 16 guide vanes along the circumference of the cyclone separator. As changing the installation angle of the guide vanes also changes the gap between the neighboring guide vanes, the cutoff size can be adjusted because the inlet velocity of the inflow aerosol is changed by the gap under a fixed operating flow rate. A CSAOI cyclone separator was devised, fabricated, and tested for performance evaluation with an operating flow rate of 1,000 L/min. The cutoff size changed from 1.4 to 12.4 μm as the guide vane angle varied between 26° and 46°. For guide vane angles of 29°, 34°, and 42°, the cutoff sizes were 2.8, 5.4, and 10.0 μm, respectively, thereby confirming that the cyclone separator can be used as a PM2.5, PM5, or PM10 sampling inlet, respectively. The developed CSAOI cyclone separator is expected to be applied to various aerosol sampling and collection devices.