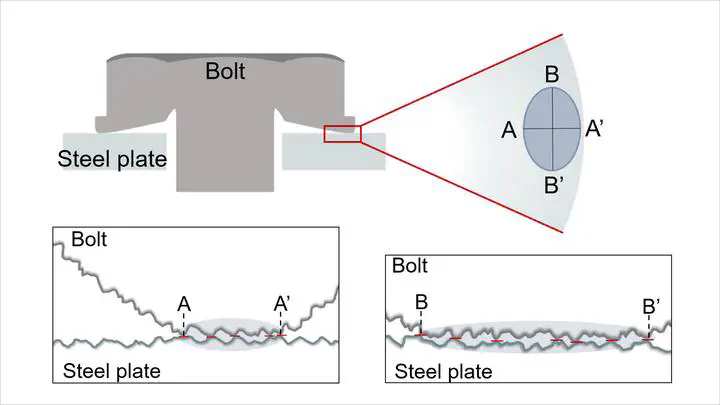

Quality control in automated bolt fastening is challenging due to the variance in appropriate tightening torque from sample to sample. This study presents an algorithm based on contact mechanics theories that predicts the bearing torque at the bolt underhead according to the surface morphology, RMS height, and hardness. The model identifies the key surface parameters to be analyzed and the predictive algorithm quantitatively calculates the frictional torque with the known surface characterization data. Different combinations of bolts and plates with a range of surface properties were tested for experimental validation, which confirms 95.3∼99.0% of accuracy of the predictive model.