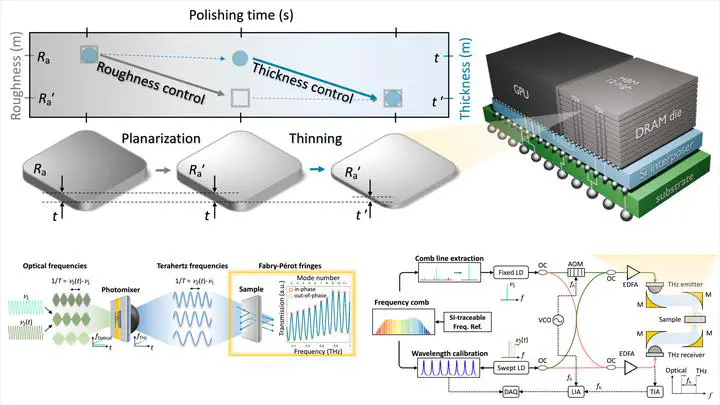

11. Frequency-comb-referenced Terahertz Fabry-Pérot interferometry for monitoring semiconductor wafer thinning process with a nanometer precision

High-precision, non-destructive thickness measurement is essential in semiconductor manufacturing. Optical methods often struggle with strong surface scattering and absorption during wafer thinning. We present nanometer-precision, non-destructive wafer thickness measurement using the absolute frequency positions of Fabry-Pérot interference modes in the terahertz frequency regime, referenced to a frequency comb. By leveraging the comb’s SI-traceable frequency uncertainty and terahertz radiation’s scattering insensitivity, this approach achieves a 58.4-nm precision in 0.2-s and 7.2-nm in 25.6-s averaging. Such unprecedented performance enables effective monitoring of wafer thinning processes (e.g., chemical mechanical polishing), crucial for advanced semiconductor packaging.